Named the White Tower or Tor Alva, this impressive structure is hailed as the world’s tallest 3D-printed building. Designed by experts from ETH Zurich, it’s set to be assembled in Mulegns, a Swiss village. With input from Nova Fundaziun Origen, it will consist of a hundred columns supporting a remarkable performance space. The tower will be printed in sections, transported, and then put together in the remote Swiss Alps village.

The White Tower, inspired by Baroque design, will stand at 100 meters tall. Supported by huge 3D-printed columns, it will feature five floors and a partly open facade. This facade, a lightweight membrane, can be removed to shield the tower’s interior from the elements. Visitors will enter the lower floors, where large columns create intimate spaces.

The White Tower will boast a spiral staircase leading visitors to each floor, gradually opening up into a spacious hall at the top. This hall will serve as a venue for concerts and theater, seating up to 45 people with a stage included. After performances, the tower will be dismantled and relocated to another site.

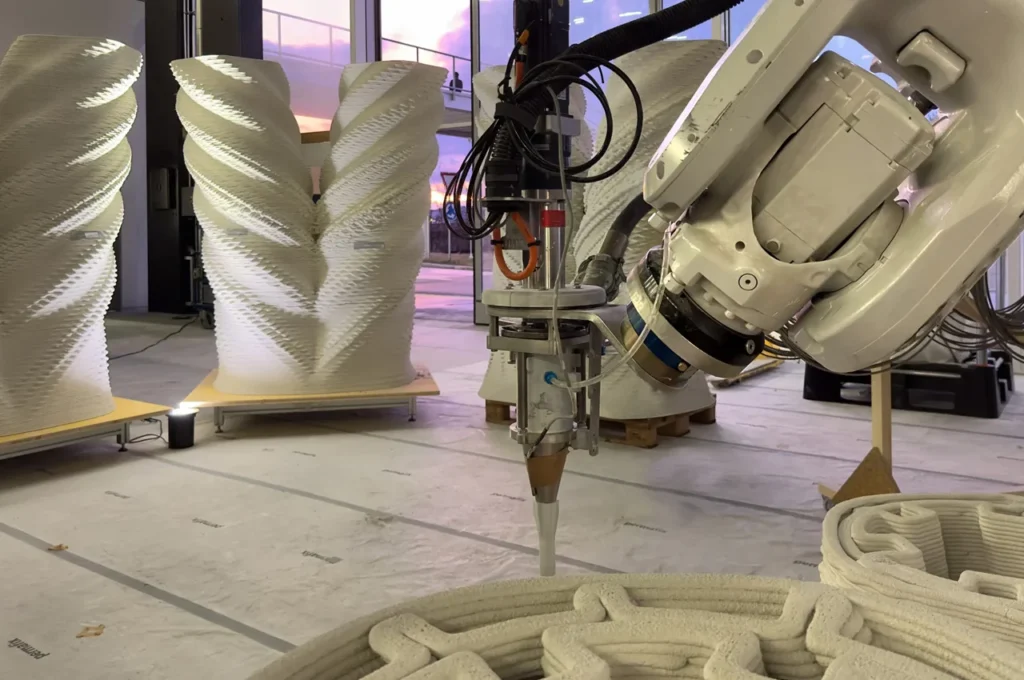

The 3D-printing of the tower will take about 900 hours, utilizing robotic printers to extrude a cement-like mixture layer by layer. These printed elements will form the basic structure of the tower, later assembled on-site to construct the White Tower.

ETH Zurich’s Digital Building Technologies explained, “Custom software designs the entire tower structure precisely, sending data directly to the printing robots. This technology allows efficient production of unique, non-standard elements, which would be difficult with traditional methods. The tower will consist of 102 3D-printed columns, filled with concrete only where structurally needed, minimizing material use. This approach reduces waste since there’s no need for concrete formwork.”